Engines & Exhaust Systems

Power plants are one of the toughest things to build for DIYers - so why not just put a new one in? ATK builds complete engines for dozens of different makes and models, from small blocks to hemi power. These powerful engines ship free and come with a two-year warranty. You'll get the sound you deserve from that motors with one of the high-performance classic car exhaust systems we stock. Eastwood has full systems along with tips, mufflers and custom exhaust kits for muscle cars and pony cars.

Internal & Body Parts

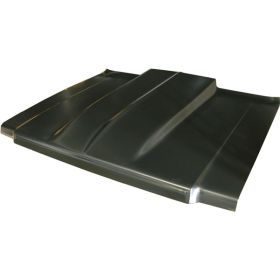

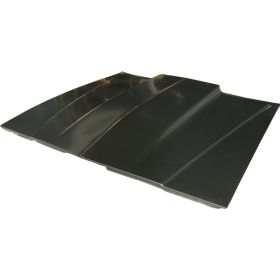

But it takes more than good power and sound for an outstanding restoration. Radiators are another cart part that can be incredibly difficult to build. If your project needs a new one, consider a Maxx Power Tri Flow Radiator with triple pass technology for cooler engine temperatures. We have caps, fans, shrouds and other accessories as well. If you're not confident in your metal-shaping skills or just don't want the hassle, we have hundreds of replacement body panels from 50's hot rods to present-day trucks. And when you're ready for the road, give yourself more stopping power with disc brake conversion kits for old-school rides.

Modern Parts for Vintage Cars

Just because you're restoring an older car doesn't mean you can't give it a little extra zip. Stop combing eBay for those hard-to-find OEM parts and come to Eastwood for a contemporary take. If there's a specific component you have in mind, contact us to learn more about what's in stock!

Auto Parts

Here at Eastwood we don't just sell tools, equipment and paint. We carry many auto parts you need to get your project on the road as well. Need a disc brake conversion to be safer in modern traffic? We have them. High performance full exhaust system for your classic or muscle car?

Auto Parts for Restorations

Sometimes it's just not possible to make a new auto part no matter how hard you try. But fret not - you might be able to find that part at Eastwood! Our customers have told us what auto restoration parts they need the most and which ones are the hardest to make. And we've responded with an assortment of pre-built parts that arrive ready to install. We have premium components for popular Ford, GM and Mopar models that are made to be as good as or better than the original.