Item #

15357Z

BRAND: Eastwood

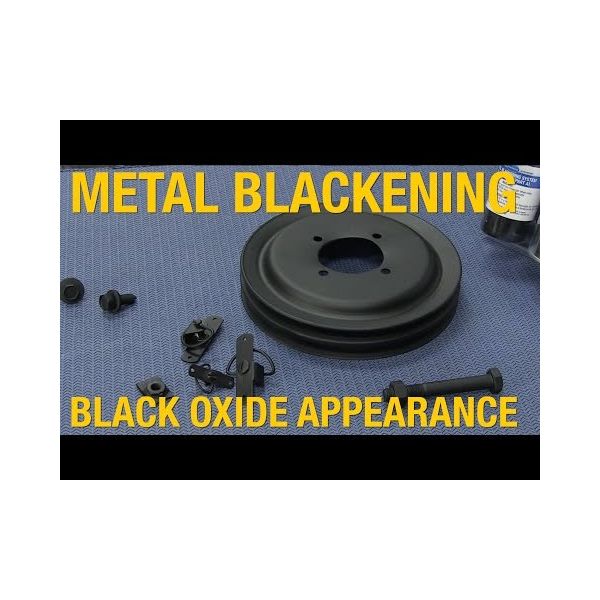

Eastwood Metal Blackening System

The look of OEM applied black oxide coating at home, and even more durable

The look of OEM applied black oxide coating at home, and even more durable

Evans HP High Performance Waterless Coolant Gallon is rated

out of

5 by

10.

The look of OEM applied black oxide coating at home, and even more durable

100% Satisfaction Guarantee Since 1978

We stand behind our solutions and customers.

- • Lifetime Tech Support

Product Overview:

Description

The look of OEM applied black oxide coating at home, and even more durable.

- Replicates OEM black oxide/phosphate finish

- Chip and chemical resistant

- Resists temperatures up to 600° F

- Protects against rust and corrosion

- Not affected by DOT 3 brake fluid or gasoline

- No special equipment, no heat cure

- For iron, steel, stainless, and aluminum

Many factory brackets and fasteners originally were given a black oxide/phosphate finish to protect them. Eastwood’s Metal Blackening System allows you to apply a factory looking finish, with no special equipment and no need to heat cure. This 2 component product protects against rust and temperatures up to 600° F. It not only replicates the look of black oxide, but the feel as well, while being even more durable.

Warranty

In the Box

Contents

Guides & Accessories

Instructions

Click here for product instructions

Safety Information

Application Tips

Application is either with the included aerosol spray or conventional paint gun or air brush. Once product is dry to the touch, approx 24 hours, parts can be assembled or placed back into service. Once parts have fully cured for 2 weeks, they will be protected from corrosion, chemicals and abrasion for years and still have that OE black oxide appearance.

Reviews

Rated 5 out of

5

by

The Last Templar from

Achieved the look I wanted

I have the older version of this product in a plastic tub that I purchased a few years ago but it still works great, I used it to get the correct look I wanted on a pair of medieval belt buckles that I made, I hammered the buckles, dipped them for 10 seconds so as to not get them too dark, let dry for a few minutes, then lightly sanded them with some 600 sandpaper, then put them in the sealing solution for two minutes and let dry a day, the results were exactly what I wanted.

Date published: 2021-01-16

Rated 5 out of

5

by

Stephen K from

Easy to apply

I bought this a while ago ,easy to apply seam to work well ,must let it cure completely a few days so it is more durable . Looks great !

Date published: 2017-10-09

Rated 5 out of

5

by

pairodocs from

Perfect results

Used for outdoor strong-ties and carriage bolts. Nearly 300 pieces. Followed directions.Excellent results.

Date published: 2016-08-10

Rated 5 out of

5

by

dlwjr from

EASY TO USE

Bought this to do my rims for my truck it would be a lot nicer if it was more product

in the kit.

Date published: 2016-07-29

Rated 5 out of

5

by

Bngrndr289 from

Easy Eastwood Metal Blackening System

Like the title says, very easy to accomplish. I bought this kit specifically for use on some aluminum items. Works pretty well from what I can see. How durable the coating is remains to be seen. And it does have some gloss to it; it's not dull by any means. More like a semi-flat black sheen. Left knurled portion of peep sight is aluminum and the right side is factory steel, with whatever blackening process they used in the late 40's.

Date published: 2015-04-15

Rated 4 out of

5

by

Dave from

Metal blackening product

The finish it gives is excellent!! The delivery system supplied did not work. The aerosol must have leaked down ??? I used my small spray gun which worked fine.

Date published: 2024-03-23

Rated 4 out of

5

by

Jay E from

Very good product

I was pretty skeptical about this product based on mixed reviews. I used this to coat two bare metal power steering master cylinder. I wanted this product because it says it will be DOT3 fluid resistant. While it remains to be seen if it can really handle that, everything else was pretty much top notch except the price. I mixed it in 2 halves, and coated the two master cylinders and about 2 dozen body bolts with the first half. I wish the hardener and base material had gradations so I could more accurately measure the mix’s, but i got it right anyway and it dried overnight to a very hard flat black that looks very even. I also cleaned up the firewall where fluid had removed some paint and repainted with some of this - this also looked really well. I cleaned the sprayer with thinner as recommend and with the second half of the product on another day I sprayed other areas that I had cleaned up on the underside of the car- this was an excellent hard finish when complete. I covered about 3-4ish square feet of surface with it. I didn’t like that the sprayer will leak if tilted too much or shaken, so that was kind of unhandy. Otherwise - I am thrilled with the results thus far. If it can really survive DOT3 fluid I will say generally very impressed, but given the high cost for low volume of product I can’t give it a full 5 stars. High 4 stars is best I can do.

Date published: 2021-04-04

Rated 2 out of

5

by

nick from

questions

is it a polymer coating? seems very similar to cerakote ...

Date published: 2020-04-26

Questions & Answers

I have an iron offset firebox on a large smoker that needs restoring. Would this product be appropriate for this purpose?

If the firebox exceeds temperatures above 600° F

NO

Date published: 2023-05-31

Looks great. Is this basically a high performance catalyzed paint? Can you tell us what it actually is, please? Thx.

The look of OEM applied black oxide coating at home, and even more durable.

Replicates OEM black oxide/phosphate finish

Chip and chemical resistant

Resists temperatures up to 600° F

Protects against rust and corrosion

Not affected by DOT 3 brake fluid or gasoline

No special equipment, no heat cure

For iron, steel, stainless, and aluminum

Many factory brackets and fasteners originally were given a black oxide/phosphate finish to protect them. Eastwood’s Metal Blackening System allows you to apply a factory looking finish, with no special equipment and no need to heat cure. This 2 component product protects against rust and temperatures up to 600° F. It not only replicates the look of black oxide, but the feel as well, while being even more durable.

Date published: 2023-07-15

Would this work on chrome door handles if the chrome is scuffed?

Yes it will.

Date published: 2023-02-09

I have the older kit, with a blackening compound to be mixed with distilled water. I have searched the booklet and all labels. What is the mix ration, compound to distilled water?

Please contact us by calling 800-343-9353 or by emailing tech@eastwood.com

Date published: 2022-01-17

do you have to buy the kit or are the part "A" and part "B" available in bulk? I want to use a spray gun and wouldn't need the spray bottle. What is the mix ratio for part "A" and part "B"?

This application and mixing instructions can be found on the instructions link on the website https://www.eastwood.com/images/pdf/15357Q_unst.pdf. It mixes 12:1 and is not sold separately. We only offer this as a complete kit.

Date published: 2020-08-22

Would this product be suitable for the bolt heads on my motorcycle, (i.e. primary cover, transmission bolts, & head bolts)?

Yes, this kit would be a great option for the applications in reference. If you have further questions or concerns please call us at 800-343-9353 or email us directly at tech@eastwood.com

Date published: 2020-02-14

Would this be durable enough to coat a pistol slide. What is the hardness rated at.

Unfortunately we strictly test for automotive use only. The ratings of this coating are:

Direct impact resistance – 160 in. lb.

-Reverse impact resistance – 160 in. lb.

-Salt Spray test – 500 hrs

-Pencil hardness – 6H

-Adhesion ASTM D3359-02 – 5B

-Taber Abrasion – 3000 cycles

-Heat Resistance – 600F

Date published: 2021-09-25

Can I apply another coat of this product a day or two later with out any type of prep. I ran out of product and purchased another kit. There are still some bare spots on my parts that, after drying are visible. Thanks

This product would not be able to be reapplied, you would have to scuff all the old paint back down or you will run into a reaction with the new coats.

Date published: 2019-07-15

We found other products you might like!

Eastwood Metal Blackening System

$104.99

In Stock