Patch Panel Fabrication Tools

When you're doing rust repair or other auto body work, patch panels can often require delicate curves and angle combinations. A metal shrinker/stretcher can be used to form a gentle radius or compound curve so your replacement panel is an exact fit. These tools form metal by either compressing (shrink) or expanding (stretch) the material with no hammering, heating or secondary cuts necessary. Design patches for trunk openings, wheel wells, door jambs, dog legs and other curved areas with these premium metal-working tools from Eastwood.

Patch Panel Fabrication Tools

When you're doing rust repair or other auto body work, patch panels can often require delicate curves and angle combinations. A metal shrinker/stretcher can be used to form a gentle radius or compound curve so your replacement panel is an exact fit. These tools form metal by either compressing (shrink) or expanding (stretch) the material with no hammering, heating or secondary cuts necessary. Design patches for trunk openings, wheel wells, door jambs, dog legs and other curved areas with these premium metal-working tools from Eastwood.

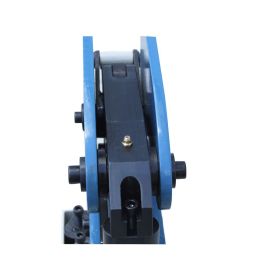

Metal Shrinker/Stretcher Units

Form sheet metal, mild steel or aluminum with one of our shrinker and stretcher systems. The R&D team has developed a pair of tools that use compound leverage from a handle to create the bends and curves you need in small metal pieces. Our standard sheet metal stretcher and shrinker combo set is ideal for most DIY workers. The Elite Deep Jaw shrinker is for heavy-duty or professional use. The tool is typically mounted on a bench or in a vise, but you can also attach it to an optional stand with a foot pedal. This increases total leverage and allows workers to hold the metal with both hands for more precise forming.

Replacement Parts & Accessories

Eastwood tools come with a full warranty against material and workmanship defects. But if you have an older shrinker/stretcher with worn-out parts, you can restore performance without needing a whole new unit. Order new steel-hardened jaw sets compatible with multiple models so you can get back to metal working. With a base plate, you can mount both the stretcher and the shrinker jaws so all you have to do is switch the handle, saving time as you work.

Expert Support of Metal Workers

Having the right tools won't help if you don't know how to use them. The Eastwood customer service team is full of DIY enthusiasts who have tested and used the equipment we sell. Call or email us today for assistance with your metal shrinker/stretcher system and tips about how to make better patch panels.