Item #

50341

BRAND: Eastwood

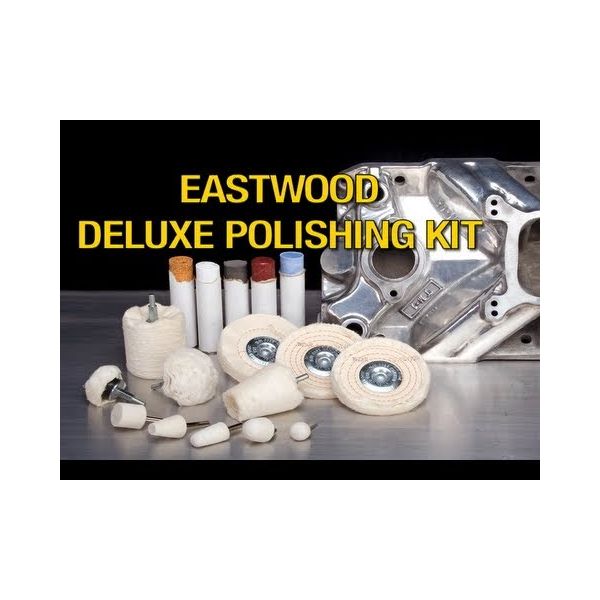

Eastwood Buffing Kit

17 pieces help you add a lustrous

shine to auto parts and more

shine to auto parts and more

17 pieces help you add a lustrous

shine to auto parts and more

shine to auto parts and more

Evercoat Everglass Filler Gallon is rated

out of

5 by

55.

17 pieces help you add a lustrous

shine to auto parts and more

shine to auto parts and more

90 day Warranty Included

100% Satisfaction Guarantee Since 1978

We stand behind our solutions and customers.

- • Lifetime Tech Support

Product Overview:

Description

The Eastwood 17 Piece Polishing Kit has everything you need to add a lustrous shine to automotive parts and more.

- Can be used on many types of metal and plastic

- Perfect for detailing auto and motorcycle parts

- Use with drill or die grinder

Eastwood's deluxe polishing kit is designed to make your steel, stainless, aluminum and plastic automotive components shine brightly! Use your electric drill, cordless drill or pneumatic die grinder for easy, effective, polishing jobs—on or off the vehicle.

- 5 compounds (one 4-oz. tube each: brown Tripoli, gray stainless, white rouge, jeweler’s rouge, blue plastic)

- 5 small felt bobs

- 2 mushroom buffs

- 2 large buffs (round, tapered)

- 3 wheels (2 spiral-sewn, 1 loose-sewn)

Warranty

In the Box

Contents

(1) 4oz. Tube of Grey Stainless Compound

(1) 4oz. Tube of White Rouge Compound

(1) 4oz. Tube of Red Jewelers Rouge Compound

(1) 4oz. Tube of Blue Plastic Compound

(1) 1/4" Shank 1" Conical Felt Bob

(2) 1/4" Shank 3/4" Bullet Felt Bobs

(1) 1/4" Shank 3/4" Semi-Round Felt Bob

(1) 1/4" Shank 1" Round Felt Bob

(2) 1/4" Shank 4" Spiral Sewn Buff Wheels

(1) 1/4" Shank 4" Loose Section Buff Wheel

(1) 1/4" Shank 2-1/2" x 3" Cylindrical Face Buff

(1) 1/4" Shank 2-1/2" x 3" Conical Face Buff

(1) 1/4" Shank 2-1/2" Semi-Round Face Buff

(1) 1/4" Shank 2" Semi-Round Face Buff

Guides & Accessories

Instructions

Safety Information

Accessories

Application Tips

Coverage depends on size of component. Kit supplied has enough product to polish two valve covers and air cleaner or complete windshield trim, door handles, etc

Reviews

Rated 5 out of

5

by

Mick from

Product worked well

Loved all the attachments to be used in all those heard to get areas.

Date published: 2023-04-13

Rated 5 out of

5

by

Potshot from

Looks Good

I haven't used this yet but looks like it will do the job.

Date published: 2022-06-22

Rated 5 out of

5

by

Logan from

Wish I would've gotten sooner

This polish kit is perfect for detailing my service jobs in the Hawaiian Kingdom, the attachments help get into all the nooks & crannies for maximum performance finishes.

Date published: 2021-08-10

Rated 5 out of

5

by

doughboy from

buffing kit

good qualty works greaat would recment to people but

Date published: 2020-05-20

Rated 5 out of

5

by

Bkxtreem from

Excellent for motorcycles

Just got this for my garage to detail my motorcycles. A good selection of pieces to detail the bikes.

Date published: 2020-04-09

Rated 5 out of

5

by

Tenstix from

Great Value! Will buy again.

Used to restore a brass fan blade. I tried diamond compound. In the end, best results were achieved with Tripoli,jewelers rouge and white rouge from this kit.

Date published: 2019-01-02

Rated 5 out of

5

by

Don B from

Great buffing kit

Used the kit to Buff several different types of materials and held up well .

Date published: 2018-12-23

Rated 5 out of

5

by

Mark88 from

Nice product

Got everything in the kit ya need from start to finish .

Date published: 2018-11-11

Questions & Answers

What is the best polish for clear plastic?

Blue buffing bars

Date published: 2023-08-18

Hi I’m planning on polishing/ buffing 4 aluminum wheels - Will this kit, would I be able to it or would you recommend other type of tools ? I would like for the wheels to get that chrome look- Shall I purchase additional items ? Thank you

This kit would certainly work for this application in reference. How many of the wheels/ buffs you need depends on the wheels and their starting condition. I would start with at least 2 kits to be safe.

Date published: 2023-07-19

I just purchased the 17 pc. buffing kit. What is the best compound to shine white aluminum, side covers on a motorcycle. Thanks

The best compound for polishing clean aluminum would be the white rouge. If the aluminum is in rough shape or badly stained use the Tripoli brown compound first then finish/final polish with the white rouge.

Date published: 2021-01-24

I have a Craftsman cordless drill that will run at a maximum 1500 rpm. I will use Aluminum brightener from Napa auto parts to clean them first .Will this kit be sufficient enough for me to polish up the aluminum wheels on my motorcycle?

The Eastwood Buffing Kit (50341) is rated at 2500rpm Buff speed or less. Your drill @ 1500rpm speed should be sufficient to buff your aluminum wheels to a high luster.

Date published: 2023-07-19

Will these work on the Milwaukee m12 mini buffer?

If it will accept a 1/4" arbor and the speed is 2500 RPM or less, yes it will work.

Date published: 2020-08-28

why dont you still have an intake kit to sand and Polish with everything you need

Thank you for inquiring about the Intake Manifold Buffing Kit that we use to sell. This was a great kit for buffing intake manifolds and other engine components. We will be offering it again in the near future.

Date published: 2020-08-18

Will the buffing wheels work with my bench polisher? It only accepts 4" wheels, maximum, and has tapered mandrels for 1" openings?

These have a 1/4" arbor so they can be used with a drill or grinder. They will not work on a benchtop polisher.

Date published: 2020-07-16

Will buffing wheels for my benchtop polisher? It only accepts 4" wheels, maximum, and has tapered spindles?

These have a 1/4" arbor so they can be used with a drill or grinder. They will not work on a benchtop polisher.

Date published: 2020-07-16

We found other products you might like!

Eastwood Buffing Kit

$44.99

In Stock