Eastwood Metal Bead Roller with Dies

1 year Warranty Included

Add an Eastwood Service Plan for additional protection?

Learn More

100% Satisfaction Guarantee Since 1978

We stand behind our solutions and customers.

- • 90 Day Returns

- • Lifetime Tech Support

Product Overview:

Description

Why Do You Need an Eastwood Bead Roller?

- Add strength and rigidity to metal panels

- Make replacement floor pans, firewalls, trunk floors and more

- Create channels, flanges and a multitude of profiles

- Fabricate decorative custom designs

Eastwood Bead Roller Features

- Handles up to a 38" wide work piece

- 4 mandrels included

- Mounts securely in your bench vise

- Forms steel up to 18 gauge and aluminum up to 16 gauge

- Industry standard 22mm shafts

- 1 Year Warranty

Add strength and rigidity to your project's sheet metal parts

The Eastwood Bead Roller is excellent for producing strengthening ribs in panels used in creating replacement floor pans, firewalls, trunk floors, inner fenders, etc. and also for creating decorative custom designs in door panels, dashes and much more with the range of included beaded Rollers.

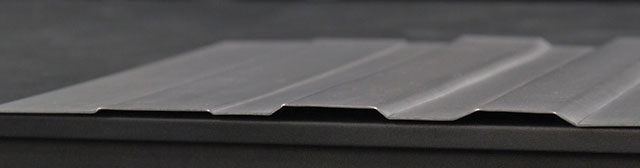

Includes Offset Dies

Also create channels, flanges and a multitude of profiles with the included offset dies. This one set of offset dies can perform the same work as many flange die sets.

Example of 3 different rib sizes created with offset dies

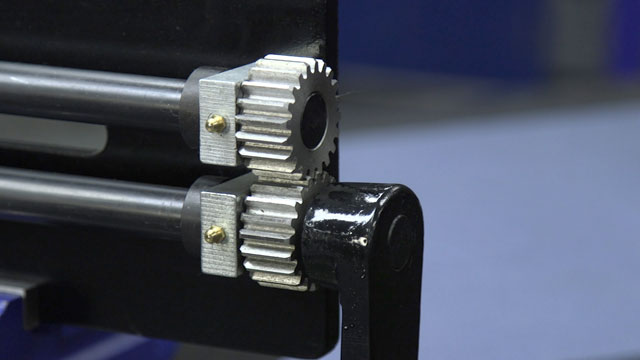

Maximum metal forming power

The gear-driven design delivers maximum forming power while requiring minimal handle force for the greatest accuracy.

Large Throat Depth

A generous 19” throat depth provides the ability to work the center of a 38” panel.

The biggest advantage of this Eastwood Bead Roller over all of the competition is the amount of accessories available to allow you to expand its capabilities while making your job easier. These accessories include a Drive Motor, Stand, Guide Fence, Table and a wide assortment of Fabrication and Forming Dies.

With the Eastwood 19-inch Manual Bead Roller, you can form panels and parts that meet exact performance specifications. This tool creates straight-line bends in up to 18-gauge steel, 20-gauge stainless steel or 16-gauge aluminum. You’ll be able to create floor pans, firewalls, truck bed floors, wheel tubs and other parts in minutes. A bead roller is also great for adding ribs, flanges and channels that increase overall strength. Use your metal forming tool to fabricate OEM-style replacement parts or great custom designs and artwork.

Our sheet metal bead roller works on pieces up to 38 inches wide. Mount it securely to a bench vise or the Eastwood Bead Roller Stand — you can use one hand to operate the crank and the other to guide the metal. Three sets of forming dies are included with more available for purchase along with accessories such as a guide fence and drive motor. We provide a one-year warranty and lifetime tech support via phone or email. Visit the Eastwood Garage for helpful tips about rolling accuracy, making louvers and m

Specifications

• Maximum panel width (working from center) = 38"

• Throat Depth: 19 Inches

• Dimensions: 31" Width x 11" High x 5" Depth

• Weight: 50 lbs.

• Constructed of 1/2" Solid Steel Plate

In the Box

Contents

(1) Crank Handle

(1) Roller Tensioning Lever

(1) Set of Offset/Tipping Dies, pre-installed

(3) Complete Sets of Roller Dies:

- 1/4” Bead Forming Dies

- 3/8” Bead Forming Dies

- 1/2” Bead Forming Dies

(6) Die Set-Screws

Guides & Accessories

Instructions

Click here for product instructions

Safety Information

Keep fingers and hands away from moving parts when operating.

Wear proper work glove and protective clothing and eye wear.

Click here to see safety products

Accessories

32046 Eastwood Bead Roller Flange Dies - 3 Sets

32047 Eastwood Bead Roller 1/4" Bead Dies

32048 Eastwood Bead Roller 3/8" Bead Dies

32049 Eastwood Bead Roller Tipping Die

32050 Eastwood Bead Roller Offset Dies

20268 Polyurethane Lower Bead Roller Forming Die

20267 Eastwood Bead Roller Metal Fabrication Forming Dies

Application Tips

What is a Bead Roller?

A Bead Roller is a machine that makes rigid lines in sheet metal to make surfaces more rugged and durable while also adding style and improving appearance. The lines bead rollers add to sheet metal prevent warping and disfigurement by adding structural integrity to the metal. Bead rollers also can be used in an artistic and creative form by allowing metalworkers to create unique designs and patterns on metal.

Bead rollers are typically available in small hand-crank units or in larger electrically powered machines. Both styles can be used to create channels, flanges, beads and artistic shapes. Additional dies can be used for tipping, rounding or even crowning sheet metal like an English Wheel.

Reviews

Questions & Answers

Where is this unit produced. I noticed everything is metric. I'm assuming it's not USA built.

I can’t justify motorizing a bead roller, but I am wondering how possible it is to form a straight bead if working alone? Thank you!

can I get hemming dies for this?

Why does the 27" bead roller not have grease fittings on shaft blocks like the cheaper models?

What is the center to center holes on the bead roller steel frame and the thread diameter and pitch?

Do you have a bead roller that bends 29 gauge steel

Do you have a 1 inch forming die that can be use with 22mm shaft roller?

Will the stand item # 20622B work on this bead roller?