Item #

22035

BRAND: Speed Blaster

Speed Blast Gravity Feed Blaster 007 RED

Easily handles "spot" rust-removal

jobs...just attach a home compressor

jobs...just attach a home compressor

Easily handles "spot" rust-removal

jobs...just attach a home compressor

jobs...just attach a home compressor

Goff's Basic Curtain Wall - GBCW - Huge Selection of Sizes-7'-24' is rated

out of

5 by

19.

Easily handles "spot" rust-removal

jobs...just attach a home compressor

jobs...just attach a home compressor

100% Satisfaction Guarantee Since 1978

We stand behind our solutions and customers.

- • Lifetime Tech Support

Product Overview:

Description

Speed Blaster will easily handle "spot" rust-removal jobs...just attach your home compressor!

- Operating Pressure 60 -100 PSI

- Working Pressure 70 -100 PSI

- Air Consumption 10 CFM - 100 PSI

- Min. Air Compressor 3 HP

- Fitting Size 1/4 NPT

- Container Capacity 26 Oz. (Vol.)

- Gun Material ABS

- Empty Weight 14 Oz.

- Max. Particle Size 14 Grit

- 2 Year Limited Warranty

- Eye protection must be worn

The Speed Blaster is perfect for small, quick, "spot" rust removal tasks when the rusted part is too big to fit in a blast cabinet.

In the Box

Contents

Guides & Accessories

Safety Information

Accessories

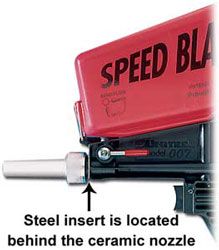

22035C Replacement Steel Insert (located directly behind the nozzle)

22035B Spot Blaster Adapter (minimizes mess)

Application Tips

Operating Pressure 60 -100 Psi

Reviews

Rated 5 out of

5

by

jonny be good from

Sand Blaster

Its great on detailing small and hard to get to area's and sand gets everywhere so its good to do it outside with a plastic covering. You can point the gun strait at or sleigthly elevaded or pointed down and it works great.

Date published: 2019-10-02

Rated 5 out of

5

by

GaryR from

Exceptional

Finally a hand held blaster for the small and tight places on our newest restoration. Simple and easy to use and no DIY’er or shop should go without one.

Date published: 2019-08-04

Rated 5 out of

5

by

Blasterbob from

Paint remover

My grandfather whittled some very delicate pieces of art. Unfortunately, my father thought it was a good idea to spray paint some of them. This little soda blaster works perfectly to remove the paint without using any stripper. Using a wet stripper of any kind would have desolved the paint right into the soft wood my grandfather used. The carving are back to the natural wood, Looks great. Thanks

Date published: 2017-10-04

Rated 5 out of

5

by

Road Kingdom from

great shop tool

Great tool for cleaning small parts ,

gets into tight areas

Date published: 2016-01-07

Rated 5 out of

5

by

GeorgeM from

Works like a champ!

I've only used for soda blasting, but it works very well with that medium and is super handy. Not sure why I didn't buy one sooner.

Date published: 2015-06-04

Rated 5 out of

5

by

yzmike from

Sticky trigger

When i first tried to use the blaster the trigger was really sticky, i had to dump the media and repeatedly depress the trigger with air only, it took a little bit but it did free up finally, The blaster works great now and with the spot blast adapter I'm pretty happy

Date published: 2015-04-21

Rated 5 out of

5

by

fatfender from

Works Great!

Works great with black beauty, aluminum oxide, & glass bead. Just have to make sure airline has a dryer or unit will clog.

Date published: 2015-04-14

Rated 5 out of

5

by

BREN from

PERFECT

WORKS PERFECT, GOOD INVESTMENT FOR SMALL JOBS, tried it as soon as I got it

Date published: 2014-12-12

Questions & Answers

will it work for motorcycle engines

Yes, you can use this for motorcycle engines.

Date published: 2020-08-17

Will this Blaster big enough to use on the entire body of my 65 bug? I dont plan to do the body in one day mind you, just curious if the spray pattern is wide enough I won’t have to feel like I’m wasting my time...

This blaster will take a considerable amount of time to strip an entire vehicle and we would recommend stepping up to a tank-style pressure blaster.

Date published: 2021-05-11

Any suggestions on air compressors? Looks like all your basic home ones won't work.

Any compressor that can supply 10 CFM - 100 PSI. Usually, 80-gallon compressors or larger 60-gallon compressors are good to run this product.

Date published: 2019-10-02

What kind of stuff would I need to put in this to blast a truck frame

This blaster will work with anything 13 grit or finer (so 13 or a larger #). So you can use anything from our Walnut shell to our Aluminum oxide media.

Date published: 2022-12-06

Will this work to take rust off from a truck frame?

This product will take rust of a truck frame when used with the correct media.

Date published: 2020-10-04

I'm interested in etch glass with it. Does it do a good job?

The tool is not as important for this application in comparison to your media selection. For glass etching your best options would be either: Glass bead or Silicon Carbide.

Date published: 2022-02-27

Is this strong enough to blast paint from vehicles?

With the right media, you can certainly use this to remove paint.

Date published: 2020-05-20

How much mess does this make ? Looking for something to use inside the car (the interior is out) to clean the inside corners of the floor for a clean lap to weld the new pans to.

Any abrasive blaster/ soda blaster will create a great deal of mess and dust in general.

Date published: 2019-01-15

We found other products you might like!

Speed Blast Gravity Feed Blaster 007 RED

$68.99

Out Of Stock. Due back April 28