Service Bulletin - #31700 and #32200 QST-30/60 Scroll Compressors

ISSUE:

Compressor is discharging oil/water mist from unloader valve, below pressure switch.

REASON:

The unit is collecting moisture in the moisture filter and oil tank which is raising oil level and resulting in oil/water being forced into the white nylon discharge hose going to the unloader valve under the pressure switch.

CORRECTIVE ACTION:

- Disconnect unit from electrical power

- With a plastic jug or 2 qt plastic container, insert hose from oil tank drain valve into container

- Drain oil from oil tank. To expedite drainage, you can raise front of compressor a few inches

- Close drain valve once oil flow stops

- Fill oil tank with 1.5 quarts of new oil

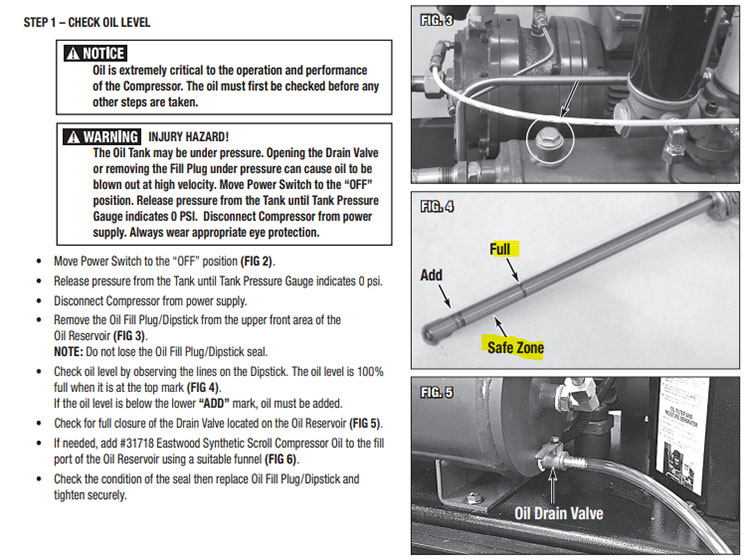

- Check oil level with dipstick. Oil level should be between upper and lower line on dipstick

- Reinstall dipstick securely on oil tank and run unit as normal

NOTE: It will take up to 5 fill/discharge cycles to purge white nylon line of residual oil - A shop rag can be loosely wrapped around unloader valve directly below pressure switch to catch oil vapor until line is cleared (pictured below)

On-Going maintenance to eliminate oil mist issue:

Drain water from oil tank Monthly

- Turn off unit at electrical power switch

- Insert oil drain hose in plastic container and open oil drain valve

- Clear liquid (water) will flow from tank

- Continue draining until liquid flow turns brown/yellow- this is good oil

- Close drain valve

- Check oil level as above

- Add oil if required, assure oil level is between upper and lower lines on dipstick

- Reinstall dipstick cap securely and run until as normal

NOTE: It is completely acceptable to run unit WITHOUT cover installed. This will facilitate draining moisture from oil tank very easy.