Plasma Cutter Consumables

Maintaining plasma cutting consumables ensures the effectiveness and quality of the cutting process. Eastwood is stocked with plasma cutter consumables, including electrodes, nozzles, swirl rings, shield cups, and gas distributors to keep you cutting.

Electrodes

Plasma cutter electrodes are typically made from copper or copper alloys to withstand the high temperatures and electrical currents generated during the cutting process. The electrode conducts electrical current from the plasma cutting power source to the workpiece, ionizing the gas and creating the plasma arc necessary for cutting. Electrodes wear out over time due to exposure to heat and electrical arcing.

Nozzles

Plasma cutting nozzles are commonly made from copper or other heat-resistant materials to withstand the intense heat generated during cutting. The nozzle constricts and shapes the plasma arc, focusing it into a narrow, high-energy stream for precise and efficient cutting. Nozzles experience wear and erosion over time due to exposure to the high-velocity plasma stream and abrasive properties of the cutting process.

Swirl Rings

Swirl rings create a vortex or swirling motion in the cutting gas, enhancing plasma stability and improving cut quality, especially in thicker materials. Like other plasma cutting components, these can wear out or become damaged over time due to exposure to heat and mechanical stresses.

Shield Cups

Shield cups, also known as retaining caps or shield caps, are typically made from ceramic or other high-temperature-resistant materials to protect the cutting torch from heat and spatter. They surround the cutting nozzle and help contain the plasma arc, directing it toward the workpiece and providing additional shielding gas coverage and also help to prevent molten metal and slag from adhering to the torch components. Shield cups can become damaged or cracked due to exposure to heat and mechanical impacts during cutting.

Gas Distributors

Gas distributors, also known as diffusers or gas baffle plates, are typically made from copper or other conductive materials and may include insulating components. These components distribute the flow of cutting gas evenly around the nozzle and into the plasma arc, ensuring consistent gas coverage and optimal cutting performance. Gas distributors often become clogged or worn over time, leading to uneven gas flow and reduced cut quality.

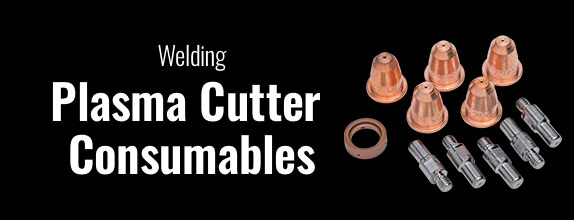

Plasma Cutter Consumables

Maintaining plasma cutting consumables ensures the effectiveness and quality of the cutting process. Eastwood is stocked with plasma cutter consumables, including electrodes, nozzles, swirl rings, shield cups, and gas distributors to keep you cutting.

Electrodes

Plasma cutter electrodes are typically made from copper or copper alloys to withstand the high temperatures and electrical currents generated during the cutting process. The electrode conducts electrical current from the plasma cutting power source to the workpiece, ionizing the gas and creating the plasma arc necessary for cutting. Electrodes wear out over time due to exposure to heat and electrical arcing.

Nozzles

Plasma cutting nozzles are commonly made from copper or other heat-resistant materials to withstand the intense heat generated during cutting. The nozzle constricts and shapes the plasma arc, focusing it into a narrow, high-energy stream for precise and efficient cutting. Nozzles experience wear and erosion over time due to exposure to the high-velocity plasma stream and abrasive properties of the cutting process.

Swirl Rings

Swirl rings create a vortex or swirling motion in the cutting gas, enhancing plasma stability and improving cut quality, especially in thicker materials. Like other plasma cutting components, these can wear out or become damaged over time due to exposure to heat and mechanical stresses.

Shield Cups

Shield cups, also known as retaining caps or shield caps, are typically made from ceramic or other high-temperature-resistant materials to protect the cutting torch from heat and spatter. They surround the cutting nozzle and help contain the plasma arc, directing it toward the workpiece and providing additional shielding gas coverage and also help to prevent molten metal and slag from adhering to the torch components. Shield cups can become damaged or cracked due to exposure to heat and mechanical impacts during cutting.

Gas Distributors

Gas distributors, also known as diffusers or gas baffle plates, are typically made from copper or other conductive materials and may include insulating components. These components distribute the flow of cutting gas evenly around the nozzle and into the plasma arc, ensuring consistent gas coverage and optimal cutting performance. Gas distributors often become clogged or worn over time, leading to uneven gas flow and reduced cut quality.