Eastwood CONTOUR® Aluminum Reinforced Repair Compound Body Filler

stronger, corrosion-resistant repair

stronger, corrosion-resistant repair

stronger, corrosion-resistant repair

90 day Warranty Included

100% Satisfaction Guarantee Since 1978

We stand behind our solutions and customers.

- • Lifetime Tech Support

Product Overview:

Description

Contour® Repair Compound is reinforced with aluminum for a stronger, corrosion-resistant repair.

- Superior corrosion resistance and adhesion

- Repair factory-leaded seams and high-strength applications

- Perfect for areas prone to moisture

- Includes hardener

Fortified with aluminum particles

Eastwood's uniquely formulated filler is fortified with aluminum particles to produce a repair with extra strength, corrosion resistance and durability in galvanized steel and aluminum. Includes Liquid Hardener.

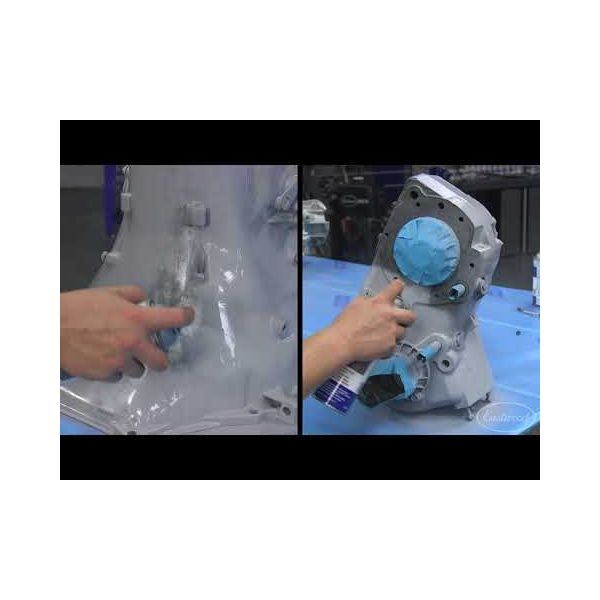

Smooth Rough Castings

A uniquely formulated filler fortified with aluminum for strength, corrosion resistance and durability. Use to repair factory leaded seams and high strength applications as well as areas prone to moisture. Its corrosion resistant properties prevent rust from coming through the repair.

If you're sanding primer or body filler you have to check out the Eastwood Elite Contour DSB Dustless Sanding Block System that gives you laser straight panels while keeping you and your shop clean because it eliminates 95% of the sanding dust.

Warranty

In the Box

Contents

Guides & Accessories

Safety Information

Accessories

Application Tips

Reviews

Questions & Answers

Can this filler be used over Galvanized steel?

Can phosphoric acid be applied over this filler?

Can I use this aluminum filler to smooth out the welds on the top side of floor pans?

Is this product suitable for marine applications?

Can this product be applied over a gray rust encapsulator? I have painted my panels with rust encapsulator to prevent rust and wanted to apply this Eastwood CONTOUR® Aluminum Reinforced Repair Compound Body Filler over seam for the two welded panels.

Will this work for covering welds on patch panels before body filler.

Can this be used to fill low spots like regular body filler.

can this be powder coated?