Eastwood Elite 200 Amp Multi-Process AC/DC MP200i Welder

3 year Warranty Included

Add an Eastwood Service Plan for additional protection?

Learn More

100% Satisfaction Guarantee Since 1978

We stand behind our solutions and customers.

- • 90 Day Returns

- • Lifetime Tech Support

Product Overview:

Description

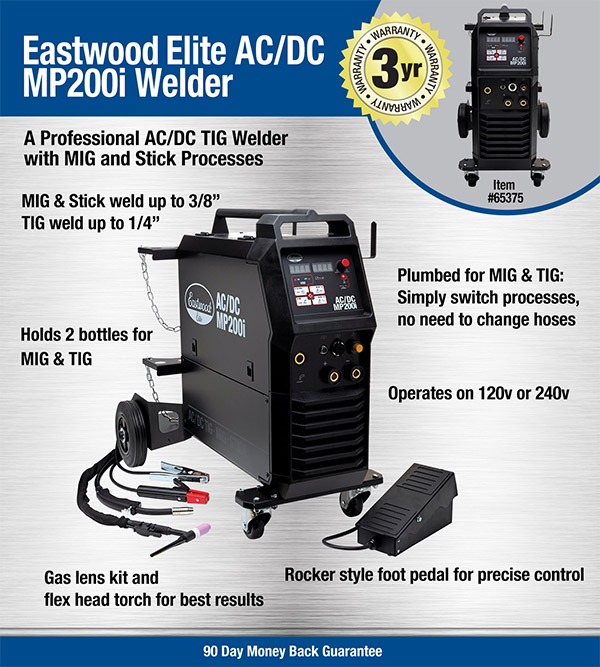

The Multi-Process Machine That Does It All, Even TIG Weld Aluminum!

Finally a TIG welder with professional features that can also MIG and Stick weld. Most multi-process machines are MIG units that only offer the option to TIG weld steel and it's often scratch start without a foot pedal. Eastwood has raised the bar with this MP welder that not only has MIG and Stick options but is a fully functioning TIG machine with high frequency start and rocker style foot pedal so you can TIG weld steel, stainless and aluminum. It's like buying a quality TIG machine that can also MIG and Stick weld!

When you want a Multi-Process machine that's built to deliver great results on both steel and aluminum with no compromises, you need the Eastwood Elite MP200i AC/DC welder. It has all of the features of a standard AC/DC TIG Welder like High Frequency Start and a Rocker Style Foot Pedal so when you switch from MIG to TIG you know you're going to get the same great results you'd expect from a dedicated TIG machine.

When you're doing a full-scale auto restoration, sometimes one welding function, whether it’s MIG or TIG, isn't going to be enough. This machine is completely plumbed for MIG and TIG welding, and the cart holds a gas bottle for each so you can almost instantly switch between functions without changing hoses and regulators like you would with other units. That means everything stays connected and ready to weld, and with a flip of a switch you can go from MIG to TIG welding when you're working on body panels, roll cages, custom-fab parts or other work.

Weld thin sheet metal or up to 3/8 inch steel and aluminum using this versatile machine. You can also stick weld or add an optional spool gun for MIG welding aluminum.

The Eastwood MP200i Multi-Process 200 Amp AC/DC Welder Features:

- Operates on either 120 or 240V

- MIG and TIG weld steel, stainless and aluminum

- IGBT inverter based power supply

- MIG weld thin sheet metal to 3/8 inch thick steel and stainless

- TIG weld steel, stainless and aluminum up to 1/4 inch

- Arc weld up to 3/8 inch steel and stainless

- Weld aluminum up to 1/4 inch with a spool gun (item 20172 sold separately)

- Holds 4 or 8 inch wire spools (11 lb. max weight)

- Square Wave Inverter

- Fully independent MIG and TIG Gas Systems

- Holds 2 bottles for both MIG and TIG welding

- Rocker style TIG foot pedal with extra long cable (16')

- Includes two gas regulators

- Dynamic Cooling Fan

- Side hooks for easy cable storage

- True AC/DC TIG welder with foot pedal and high frequency start!

- WP17 Flex Head TIG Torch included for greater flexibility

- Includes Gas Lens kit for improved performance

- Awesome Duty Cycles on all functions to keep you welding

Specifications

| Input Voltage (V) | 240 VAC, 50/60 Hz, 1 Phase and 120 VAC 50/60 Hz, 1 Phase |

| No Load Voltage (V) | 68V |

| Rated Input Current (Amps) 240V | MIG = 34.2, TIG = 25.7, ARC = 40.0 |

| Rated Input Current (Amps) 120V | MIG = 20.0, TIG = 20, ARC = 19.2 |

| Output Current Adjustment (Amps) 240V | MIG = 40-200, TIG (DC) = 5-200, TIG (AC) 10-200, ARC = 20-200 |

| Output Current Adjustment (Amps) 120V | MIG = 40-120, TIG (DC) = 5-120, TIG (AC) = 10-120, ARC = 20-120 |

| Duty Cycle 240V | MIG = 40% @ 200 AMPS / 100% @ 130 AMPS, TIG = 50% @ 200 AMPS / 100% @ 140 AMPS, ARC = 40% @ 200 Amps / 100% @130 AMPS |

| Duty Cycle 120V | MIG = 60% @ 80 AMPS / 100% @ 60 AMPS, TIG = 60% @ 100 AMPS / 100% @ 80 AMPS, ARC = 60% @ 60 Amps / 100% @50 AMPS |

| MIG Wire Size | .023 to .035 |

| Power Factor | 0.73 |

| Efficiency (%) | 80% |

| MIG Wire Feed Speed (in/min) | 35 - 590 Inches Per Minute |

| Pre Flow Time (seconds) | MIG 0, TIG 0.25 |

| Post Flow Time(seconds) | MIG 1.0, TIG 0 - 30 |

| TIG Welding Starting Method | High Frequency Start |

| Cooling Method | Dynamic Cooling Fan (only runs when required) |

| Gas System | Fully Independent MIG and TIG Systems |

| Gas Flowmeter | Gas Flowmeter, CO2/Argon Compatible |

| Welding Gas Bottle Capacity | Two 40-125 cu ft Cylinders |

| Dimensions | 35.20" x 19.88" x 30.28" |

| Weight | 95.68 lbs. (43.4 kg) |

| Plug Type | NEMA 6-50P |

| Wire Spool Sizes | 4 or 8 inch wire spools (11 lb. max weight) |

The rated Duty Cycle refers to the amount of welding that can be done within an amount of time. The Eastwood Elite MP200i when TIG welding has a Duty Cycle of 50% at the full 200 Amps. It is easiest to look at your welding time in blocks of 10 Minutes and the Duty Cycle being a percentage of that 10 Minutes. If welding at 200 Amps with a 50% Duty Cycle, within a 10 Minute block of time you can weld for 5 Minutes with 5 Minutes of cooling for the welder. If the Duty Cycle is exceeded, the welder will automatically shut off, however the fan will continue running to cool the internal components. When a safe temperature has been reached, the welder will automatically switch the Welder output back on. To increase the Duty Cycle you can turn down the Voltage Output control.

In the Box

Contents

- Included in 2 boxes

- Eastwood Elite 200 Amp AC/DC Multi-Process Welder

- Rear wheel assembly

- Front caster assembly

- (2) Double welding gas cylinder bracket

- (15) M5 x 12mm screws

- (3) M5 nuts

- (6) M5 Flat washers

- (3) M5 lock washers

- (2) Gas cylinder chains

- (2) Shielding gas hoses

- (1) Ground clamp with 14.8' cable

- (1) MIG welding gun with 8' cable and 0.030" contact tip installed

- (1) 0.030" (0.8mm) contact tip

- (1) 0.035" (0.9mm) contact tip

- (1) Contact Tip Wrench

- (1) Flex Head TIG Welding Torch (WP-17F), with 12’ cable and 3/32” Gas Lens Collet Body, #8 “Gas Lens-Style” Gas Cup, 3/32” Collet, Long Back Cap, Collet Body Installed

- (1) 1/16" Collet

- (1) #8 Gas lens style gas cup

- (1) 1/16" Gas lens collet body

- (1) Tungsten - 3/32" x 6", Red

- (1) Foot pedal (no adjustment dial) with 16' cable

- (1) Electrode Holder for Arc Welding

- (2) Cable hanging hooks

- (2) Gas regulators (CO2/Argon)

- (1) Adaptor Cord (24")

- Instruction Manual

Guides & Accessories

Instructions

Click here for product instructions

Click here for welder settings chart.

IMPORTANT NOTE: When setting up the machine for TIG welding, ensure that the Ground Cable and Clamp are connected into the Positive (+) Connection (Page 22 of the instructions). TIG welding is an Electrode Negative process, and the Ground Cable must be installed in the Positive (+) Connection.

The original manual (Rev 1 on back of booklet) incorrectly states the opposite connection method. The image in the booklet is correct. Please click the link above for the revised instruction sheet.

Safety Information

Accessories

What is the difference between this Elite MP200i AC/DC machine and the older Elite MP200i (20569)?

This unit has a lot of additional features that make this a more versatile machine. This new unit can TIG weld aluminum while the older unit can only TIG weld steel. This unit comes with a rocker style foot pedal for precise amperage control for TIG welding while the older unit does not have a foot pedal and relies on the torch trigger to turn the amperage on and off and doesn't have the ability to raise and lower the amps as you are welding.

This newer unit comes with casters attached to the machine and doesn't need a cart. It also holds two gas bottles. It also is fully plumbed for two bottles and doesn't require hoses to be changed when going from MIG to TIG welding. The older unit must be set on a cart and hoses must be swapped when changing welding functions. The newer unit also comes with an upgraded flex head torch with gas lens kit for the best welds, even in tight areas.

What is High Frequency Start for TIG welding?

High Frequency Start (HF) allows the operator to position the tungsten electrode near the metal to be welded and simply press the torch trigger or foot pedal to start the arc. HF is typically found on professional TIG welding machines with AC/DC function that also allows you to weld both steel and aluminum. This is a preferred method over lesser units that use a Scratch Start system that is not user friendly because it makes the operator touch the tungsten to the metal to be welded to start the arc. This makes it very difficult to maintain a good clean tungsten because it can easily stick to the material to be welded.

What does AC/DC mean in TIG welding?

DC polarity means the machine can weld steel. AC means it can weld aluminum. An AC/DC machine has the capabilities to weld both steel and aluminum and is typically the preferred machine for fabrication because of the ability to weld both materials.

What is the best way to sharpen a tungsten?

A dedicated grinder should always be used to sharpen a tungsten. If you use a standard bench grinder that is used to grind other metals, the debris from the grinding wheel will contaminate the tungsten and create a bad arc and poor welds. We suggest a dedicated hand held TIG Tungsten Grinder to sharpen tungstens and get the best TIG welds.

Reviews

Questions & Answers

Whats the difference between a MP200i vs the MP250i? And which one would you recommend?

The MIG cord is pretty short. Is there another cord I can use to get more length?

will this machine run an 8in spool?

Can .045 wire be used in this machine?

Can I run spool gun with the mp200i?

Is the tig only high frequency start or do have lift or scratch scratch start options? I worry about the high frequency start in close proximity to electronics, especially car systems and computers.

Does the tig torch provided have a finger switch?

Does this unit do spot time on mig for spot building