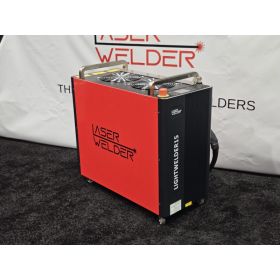

Laser Welders

Laser welding machines generate a high-intensity laser beam using either fiber lasers, CO2 lasers, or solid-state lasers. These produce a concentrated beam of light that can be precisely controlled. This focused beam generates intense heat when it strikes the surface of the workpiece.

When the laser beam contacts the metal surface, it rapidly heats and melts the material. As the beam moves along the joint, the molten metal solidifies, creating a strong bond between the parts. Unlike traditional welding methods that require physical contact between the welding electrode or filler metal and the workpiece, laser welding is a non-contact process. This eliminates the risk of contamination from welding consumables and minimizes distortion in the workpiece.

This type of welding offers exceptional control over the process, allowing for precise control of beam intensity, duration, and spot size. This precision enables welds with minimal heat-affected zones and distortion, resulting in great-looking high-quality welds.

Laser Welders

Laser welding machines generate a high-intensity laser beam using either fiber lasers, CO2 lasers, or solid-state lasers. These produce a concentrated beam of light that can be precisely controlled. This focused beam generates intense heat when it strikes the surface of the workpiece.

When the laser beam contacts the metal surface, it rapidly heats and melts the material. As the beam moves along the joint, the molten metal solidifies, creating a strong bond between the parts. Unlike traditional welding methods that require physical contact between the welding electrode or filler metal and the workpiece, laser welding is a non-contact process. This eliminates the risk of contamination from welding consumables and minimizes distortion in the workpiece.

This type of welding offers exceptional control over the process, allowing for precise control of beam intensity, duration, and spot size. This precision enables welds with minimal heat-affected zones and distortion, resulting in great-looking high-quality welds.